Gloves Manufacturing Process, Raw Materials, Production

Gloves are a very valuable and useful product as a rubber related product. Gloves manufacturing process can be different according to the gloves type. Gloves are categorized under different categories depending on their use and the raw material used. In this tutorial, we will look raw materials, production processes, quality testing, etc. of gloves production.

Written by: Chamidhu Lakpriya, (undergraduate), Manufacturing Engineering, University of Peradeniya,

Gloves are divided into two main categories.

- Natural rubber - Latex gloves: Latex gloves are made of natural rubber latex. The latex taken from natural rubber latex is mixed with processing chemicals including zinc oxide (ZnO), sulfur (S), accelerators, pigments, stabilizers, etc.

- Synthetic rubber

Synthetic rubber gloves

Nitrile gloves and vinyl gloves are two types of synthetic rubber gloves.

Nitrile gloves

The Nitrile Butadiene Rubber (NBR) is a copolymer which is used for nitrile gloves.

.jpg)

Chemical compounds, butadiene and acrylonitrile in NBR are combined by a process known as copolymerization. Butadiene gives the chemical resistance and the acrylonitrile gives the flexibility to the gloves.

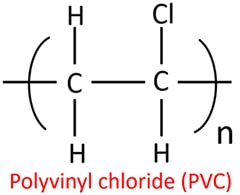

Vinyl gloves

Vinyl gloves are made of polyvinyl chloride (PVC) monomers alone. The plasticizer is added to the PVC for make the material flexible.

The gloves making process is same for the both categories.

The main steps of the manufacturing process

- Cleaning process

- Dipping process

- Per – Leaching process

- Vulcanization process

- Post – Leaching process

- Slurry dipping

- Stripping out

- Quality Check

In the gloves making process, the hand shaped molds are driven throughout the entire process on a production line, subject to the processes describe below. The gloves shaped molds are made of ceramic/aluminum or plastics capable of withstanding high temperature.

Cleaning process

Initially the ceramic hands refer to a cleaning process. This is done by several cleaning agents contained in several tanks.

Acid tank

- Temperature 550C

- The gloves shaped ceramic models are dipped into the acid tank.

Cleaning former

The ceramic hands twirl into round revolving brushes.

Rinse tank

- Ph = 5-6

- Temperature = 65-750C

- After the rinse tank molds are dripped into alkaline tank

Alkaline tank

- Sodium hydroxide (NAOH)

- Temperature 550C

- After the alkaline tank ceramic hands go through the drying process.

Drying process

- Cleaning by filtered air

- Temperature 1200C

- After the alkaline tank ceramic hands go through the drying process.

This cleaning process is very valuable in removing the dirt from the surface of the hands and maintaining the proper condition required for applying the coats.

Dipping process

When the cleaning process is complete the dipping process begins. It goes through a two main processes.

- Apply the first coat

- Appling the latex coating

Apply the first coat

The materials contained in cating.

- Calcium nitrate (Ca(NO3)2)

- Calcium carbonate (CaCO3)

Ceramic hands are dipped into a mixture of Calcium nitrate and Calcium carbonate solution.

Nitrates (NO3-) coming from calcium nitrate determine the thickness of the coating by placing rubber latex particles on the ceramic hand while the carbonates help the gloves release from the ceramic hands.

Then ceramic hands with thin coating are dried using air dry.

Appling the latex coating

Ceramic hands with first coat drip in to the latex tank. In this part latex can be either natural or synthetic.

- Natural latex: Natural gloves (Natural rubber), Natural rubber latex comes from the rubber tree which is scientifically called

as "Hevea brasiliensis".

- Synthetic latex:

Nitrile gloves (Synthetic rubber)

The nitrile butadiene rubber (NBR) used for nitrile gloves. NBR contains butadiene and acrylonitrile. Acrylonitrile increase the chemical resistance of gloves. Butadiene create flexibility and tear resistance of the gloves.

Synthetic latex: Nitrile gloves (Synthetic rubber)

The nitrile butadiene rubber (NBR) used for nitrile gloves. NBR contains butadiene and acrylonitrile. Acrylonitrile increase the chemical resistance of gloves. Butadiene create flexibility and tear resistance of the gloves.

- In this process the mil thickness of the gloves depends on duration of the dipping time.

- The concentration of the latex solution should be maintained between 10% and 60%.

- The latex reacts with the chemical coating on the ceramic and becomes gel-like.

Per – Leaching process

In leaching process residual calcium nitrate and soluble protein are removed from latex film by using hot water. Temperature maintain between 70 - 80 0C during this process.

Vulcanization

After the leaching process they head into an oven for vulcanization process. It makes rubber stronger and elastic. Gloves go through the oven at 1300C in 30 minutes.

Post – Leaching process

The gloves are then passed through another hot water tank for post – leaching process. That process is helps to remove the additional residue present in the gloves.

Slurry dipping

This process is done to provide coating with a powder or powder – free materials to remove the surface tack and thus to improve the donning of the process. The use of powder for this process is currently at a very low-level course of powdered gloves resulting the excessive of skin allergy cases.

Therefore, powder free process is currently used.

There are two of powder – free process.

- Chlorination

- Coating

Chlorination

The chlorination process controls the surface grip characteristics. The process of chlorination affects the mechanical properties of the gloves. For this reason, the chlorination process must be caring out accurately, giving the desired condition.The chlorination is a cycle process involves following steps.

- Prewashing

- Exposure to chlorine solution

- Neutralization

- Rinsing

- Drying

The chlorination reduces the grip characteristics on the surface. The chlorination process is done ones or twice as required.

Coating

In this process, a polymer coating is applied to the surface of the gloves. Typical coating materials are Acrylates (CH2=CHCOO-), urethanes (C3H7NO2), and even nitriles (R−C≡N) have been used as surface coatings for medical gloves.

Categories of coatings

The coating can be categories as hydrogels and non-hydrogels.

- Hydrogels - Water is absorbed and becomes swollen and slippery

- Non – hydrogels - Water is repelled and act as powdered surface.

Methods of applying coats

There are two methods of applying coating to gloves.

- On – line coating: Coating just before the final oven drying.

- After – processed coating: Apply the coating as soon as the gloves are washed after the manufacturing process is over.

Stripping out

The gloves are stripping out from the ceramic hand after the entire manufacturing process is completed. Gloves made of natural rubber can be removed by a mechanical process, but gloves made of synthetic rubber are stripping out by humans. Course of they are bit stickier than the natural latex one.

Quality check

End of the manufacturing process, check the product quality to detect defects. Several types of process are using to check the week spots and holes. The processes various according to the nature of the glove. Air testing, water testing and mechanical testing are used.